Feature

1. Thick film non-inductive power resistors are generally attached to the system radiator to enhance the heat dissipation of the resistor. Here, because the resistor bottom plate is attached to the system radiator, the resistor dissipates the heat through the heat exchange between the bottom plate and the radiator. The ambient temperature here refers to the temperature of the resistor bottom plate, generally based on the center of the bottom plate. The temperature is a reference.

2. Power level: 100W

3. It is non-inductive, resistant to high voltage, small size and high power, long life, good moisture resistance, and stable electrical performance.

4. Lead-out ends are led out with tinned copper wire

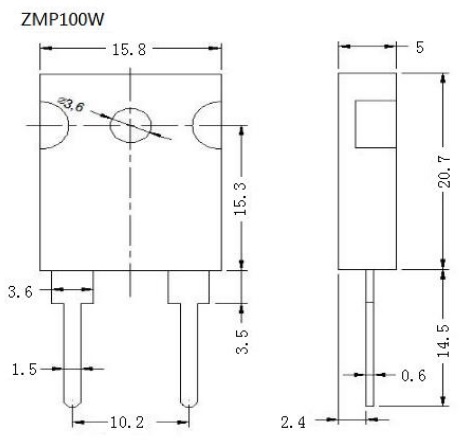

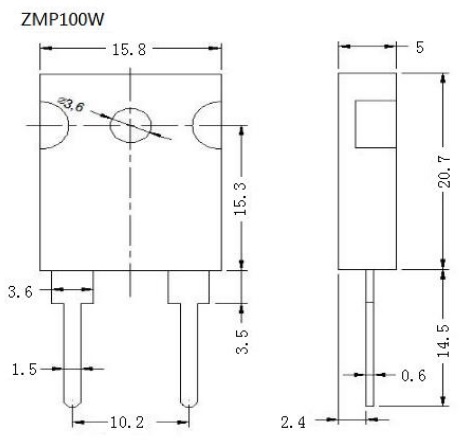

Structure

1. Using the screen printing method, the printed layer is a resistive film with a thickness of tens of microns, which is sintered at a high temperature. The matrix is 96% aluminum oxide ceramics, which has good thermal conductivity and high mechanical strength. The resistive film layer adopts noble metal ruthenium-based slurry, and the electrical performance is stable.

2. The process flow is generally electrode printing→electrode sintering→resistance printing→resistance sintering→dielectric printing→dielectric sintering, and then through the processes of resistance adjustment, welding, and encapsulation.

Applications

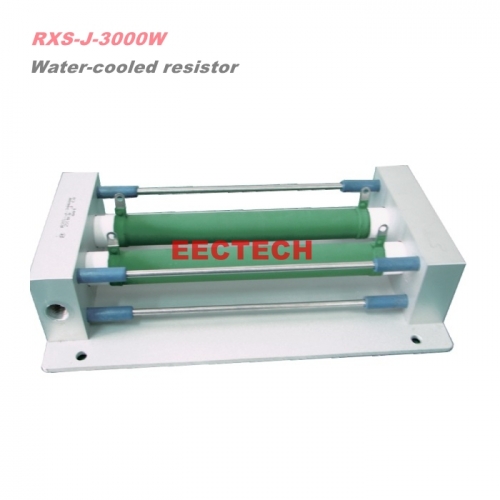

Variable speed drive, power supply, control equipment, communication, automatic control, engine control, power electronics, medical equipment, power transmission, capacitor voltage equalization, capacitor discharge, power load, automotive electronics, induction heating, power supply equipment, electrical transmission, reactive power Compensation, RC absorption and discharge, and other power electronics industries. Wind power, photovoltaic power generation and other new energy fields

| Model |

Rated Power(W) |

Main parameters |

| (25℃) |

Maximum working voltage |

Insulation withstand voltage |

inductance |

Lead-out |

Resistor installation |

| ZMP |

100W |

700VDC |

1.8KVDC |

No inductance |

Tinned copper wire |

M3 |

Remark:

Remark:

1. The resistance value is customized according to the customer

2. The resistance accuracy is generally ±5%, and it can be made as required by ±0.5%~±5%

3. The unmarked tolerance does not exceed ±0.4

Notice:

If there are special requirements or the parameters exceed the above standards, the supply can be negotiated

For delivery time:

Please contact us for checking the delivery time before placing your order.

Generally, we will dispatch the items within 7 days upon order confirmation; some items may need 20~25 days to get ready for delivery, then we will try our best to dispatch as soon as possible, or we will contact you and offer advice.

For Bulk order:

If you would like to place a bulk order, please contact us for better price and better delivery cost.

Product reviews can be carried out after the member login, please

click here to login

USD

USD EUR

EUR GBP

GBP