Features:

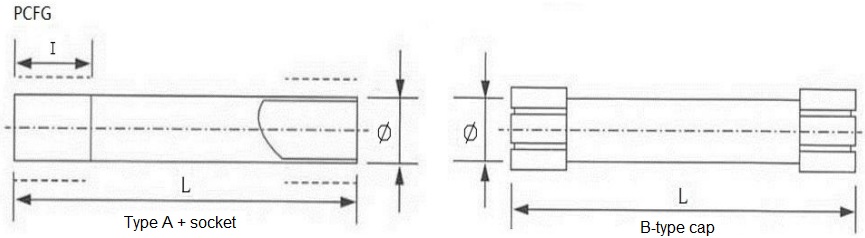

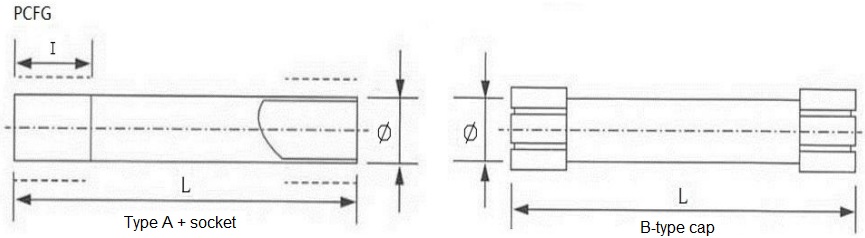

1) High power & high frequency non- inductive carbon film resistors can be divided into PCF high power non- inductive carbon film resistors and PCFG high power non -inductive high voltage carbon film resistors.

2) PCF has non -inductive characteristics ,can withstand high power,which is suitable for high current and high frequency circuits or used as false load and absorption resistors.

3)PCFG high power non- inductive high frequency carbon film resistor has wide resistance value range, high power density, good overload performance,non- inductive, resistant moisture and stable performance.

It can meet the requirements of high voltage, high power, high resistance value and non- inductive at the same time.

Structure:

1)PCF and PCFG high-power non-inductive high-frequency carbon film resistor tube end is silver or gold as electrode, very low inductance, non-spiral cutting, fine-tuning resistance value.

2)PCF and PCFG high-power non- inductive high-frequency carbon film resistors are made at high temperature. Special high-power carbon film technology is used to attach the carbon film oxide to the high aluminum ceramic tube with high aluminum content of more than 96%, and glass glaze is applied to protect the electrical and mechanical properties of the product,with small volume, high power and higher resistant heat .

3)PCF and PCFG high-power non -inductive high-frequency carbon film resistors are coated with a special glass coating on their inner and outer surfaces, which have small volume, higher resistant heat and larger power capacity.

Unlike traditional wire wound resistors, PCF and PCFG series resistors offer superior stability at high frequencies and excellent durability against transient voltage surges.

Application:

1)It is suitable for high voltage electronic equipment,used as load resistors and discharge resistors;

2)The current detection resistor is used in various switching power supplies and modules;

3)Used for high power AC and DC motor control, start, speed regulation .

| Model |

Rated Power (W) |

A Type Dimensions (mm) |

B Type Dimensions (mm) |

Resistance range |

Resistance accuracy |

Installation method |

| (40℃) |

Φ |

L |

Φ±0.5 |

L |

| PCFG |

100 |

20±1.5 |

100±2 |

22±0.5 |

110-1+1.5 |

1R-900R |

±5%(J)

±10%(K)

±20%(M) |

A type (card seat) OR B type (cap type) |

| PCFG |

120 |

25±2 |

100±2 |

27±0.5 |

100±1 |

1-10M |

| PCFG |

150 |

20±1.5 |

150±2 |

22±0.5 |

160-1+1.5 |

2R2-900R |

| PCFG |

180 |

25±2 |

150±2 |

27±0.5 |

160±1 |

2-15M |

| PCFG |

200 |

20±1.5 |

200±2 |

22±0.5 |

210-1+1.5 |

3R3-900R |

| PCFG |

250 |

25±2 |

200±2 |

27±0.5 |

210±1 |

2R2-20M |

| PCFG |

300 |

25±2 |

250±2 |

27±0.5 |

260±1 |

3-25M |

| PCFG |

375 |

25±2 |

300±2 |

27±0.5 |

310±1 |

3R3-30M |

| PCFG |

500 |

25±2 |

400±2 |

27±0.5 |

410±1 |

4R7-50M |

| Resistance temperature coefficient PPM |

≤150 |

≤250 |

≤500 |

Notice:

Notice:

If there are special requirements or the parameters exceed the above standards, the supply can be negotiated

For delivery time:

Please contact us for checking the delivery time before placing your order.

Generally, we will dispatch the items within 7 days upon order confirmation; some items may need 20~25 days to get ready for delivery, then we will try our best to dispatch as soon as possible, or we will contact you and offer advice.

For Bulk order:

If yo

Product reviews can be carried out after the member login, please

click here to login

USD

USD EUR

EUR GBP

GBP