Enter the precision production system of the United States, Germany, and Japan!

Features

1. Automobile speed regulating resistance has the characteristics of high power, small size, low temperature and stable performance.

2. A single resistor can achieve one or two or more resistance values.

3. According to different car models and customer requirements, the resistance matrix can be round, flat or square, and the resistance flat wire or round wire can also be corrugated.

4. It can be installed and assembled according to customer requirements. There are many kinds of colors.

5. Thermal fuses with different temperatures and different requirements can also be equipped according to customers.

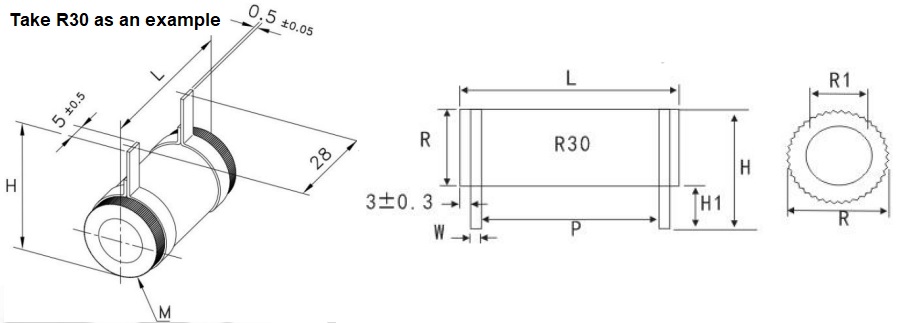

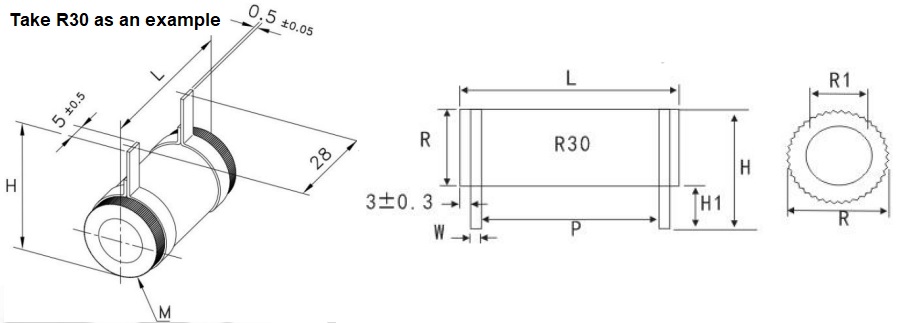

Structure

1. Use high temperature resistant ceramics as the resistance matrix, which has high heat dissipation.

2. The resistance alloy wire with high stability is selected, wound according to the rigorous process and spot-welded on two or more conductive terminals, so that the resistance has strong impact resistance and high stability. Non-combustible paint encapsulation, so that the resistance wire is effectively protected, thereby increasing its service life

3. Assemble thermal fuse and plastic base according to different car models and customer needs to assemble into finished products

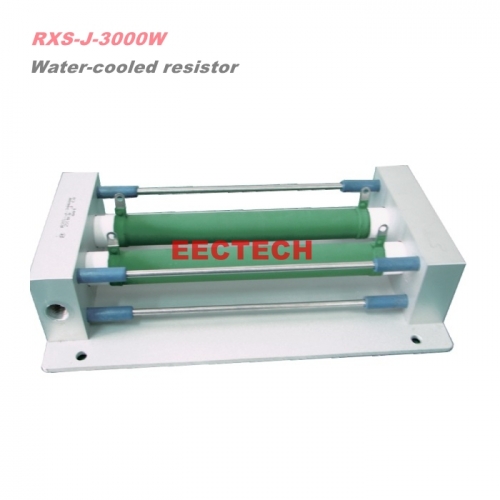

Application

1.Production of a full range of round tube ceramics, flat ceramics, square ceramics, aluminum tube type, aluminum shell type and more than 50 types of automotive air-conditioning resistors, used in Japanese, American, German and other models

2.Automobile speed control resistance is also called automobile resistance, automobile blower resistance, automobile air conditioner speed control resistance and so on.

3.Common resistance values are R24, R25, R30, R35, R38, R69 and other resistance values

| R30 unit:mm |

| Characteristic |

L |

M |

H |

W |

R1 |

H1 |

P |

Current |

Maximum current

(A) |

Maximum continuous power (W) |

Resistance range

(R) |

| Data |

39.5-42 |

19.5-22 |

30-33 |

4-5 |

12-14 |

12-14 |

24-25 |

6-15 |

25-40 |

63-115 |

0.3±10﹪ |

Notice:

Notice:

1. The resistance matrix can be round, flat or square according to different models and customer requirements. The resistance winding wire can be flat wire or round wire, or corrugated winding.

2. The plastic bottom seat can be installed and assembled according to customer requirements, and the mold can be customized, and there are many colors.

3. Thermal fuses with different temperatures and different requirements can also be equipped according to customers.

For delivery time:

For delivery time:

Please contact us for checking the delivery time before placing your order.

Generally, we will dispatch the items within 7 days upon order confirmation; some items may need 20~25 days to get ready for delivery, then we will try our best to dispatch as soon as possible, or we will contact you and offer advice.

For Bulk order:

If you would like to place a bulk order, please contact us for better price and better delivery cost.

USD

USD EUR

EUR GBP

GBP